Vogelsang's VX Rotary Lobe Pump Meets Crossland Tankers' Innovation: A Perfect Duo

When innovation meets dedication, extraordinary things happen. The combination of Vogelsang's VX rotary lobe pump and Crossland Tankers' state-of-the-art slurry tanker form a perfect partnership that's reshaping the landscape of slurry transport.

To gain a deeper insight into this partnership, let's delve into the features and performance aspects that make this collaboration a game-changer.

From repairs to industry leaders

Crossland Tankers began its journey as a humble tanker repairs and servicing company in 1988. Fast forward to today, and they've evolved into one of the leading road tanker manufacturers in Ireland and the UK. With over 130 employees and manufacturing sites in Northern Ireland and England, Crossland Tankers continues to grow, building around 220-250 truck-mounted tanks and tanker trailers per year – that’s roughly one unit every working day.

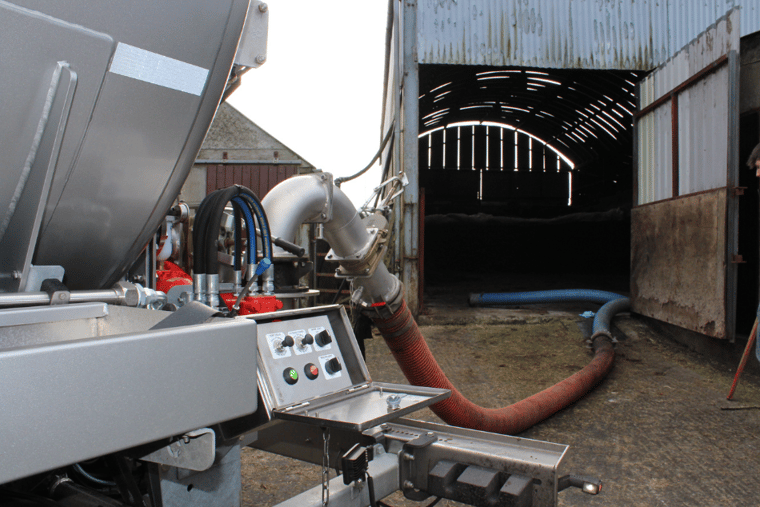

Built for hauling material by HGV, Crossland Tankers' latest product takes them back to their roots – serving farm equipment. Originating from the need to transport pig slurry, this new slurry tanker at a size of 33,000 litres showcases the company's journey from servicing a piggery in Swatragh to becoming a key player in the road tanker industry.

The Crossland-built slurry tanker enhances farm efficiency for those seeking larger capacities compared to traditional models. With the capability to transport more slurry in a single trip, time is saved, and essential tasks can take precedence. Designed for optimal fuel efficiency, this intelligent choice reduces fuel costs and the frequency of maintenance, providing a cost-effective solution. Choosing a Crossland-built tanker guarantees peace of mind with certifications such as ISO 9001, Pressure Equipment Directive, and European Whole Vehicle Type Approval, ensuring alignment with the latest standards.

“We have a good heritage in designing tankers for waste industry and this one has been designed to be robust, reliable, and less expensive that vacuum tankers that could be used for this kind of work too. Giving the high cost of farm machinery and the increase in red diesel, by using the Crossland Slurry Tanker, it will improve farm efficiency and lower costs for farmers. We know the roads our farmers will drive down so this thing is built to be bullet proof.”

Stephen McFerran, Business Development Manager at Crossland Tankers

Vogelsang's VX Rotary Lobe Slurry Pump: unveiling the features

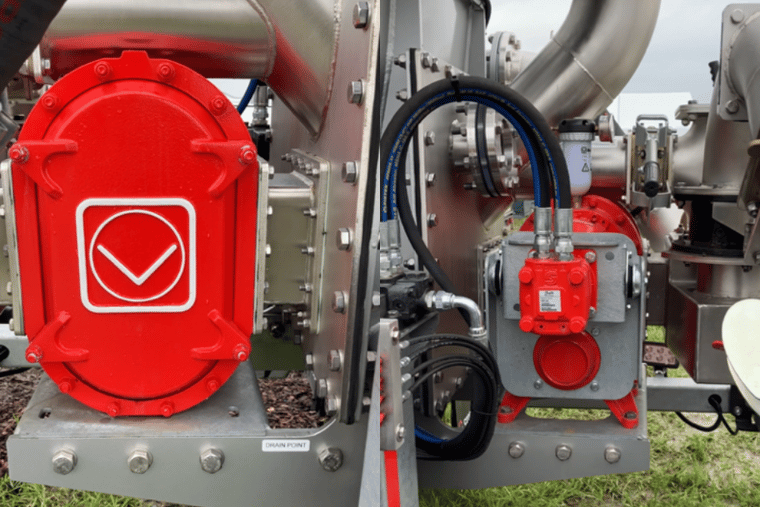

In the world of tankers, a robust pump is crucial, particularly for this powerful slurry tanker. The Vogelsang VX 186-184Q rotary lobe pump was chosen as the powerhouse for efficient slurry pumping, achieving a flow rate of 150m3 per hour or 2500 litres per minute.

Conor Quinn, Engineering Development Manager for Crossland Tankers, explains, “The Vogelsang pump provides a lot of the functionality of a traditional vacuum pump in terms of suction. However, the higher discharge pressure gives a distinct advantage when it comes to pumping off over long distances. The pumping rates are also quite high when you consider the physical size of the unit.”

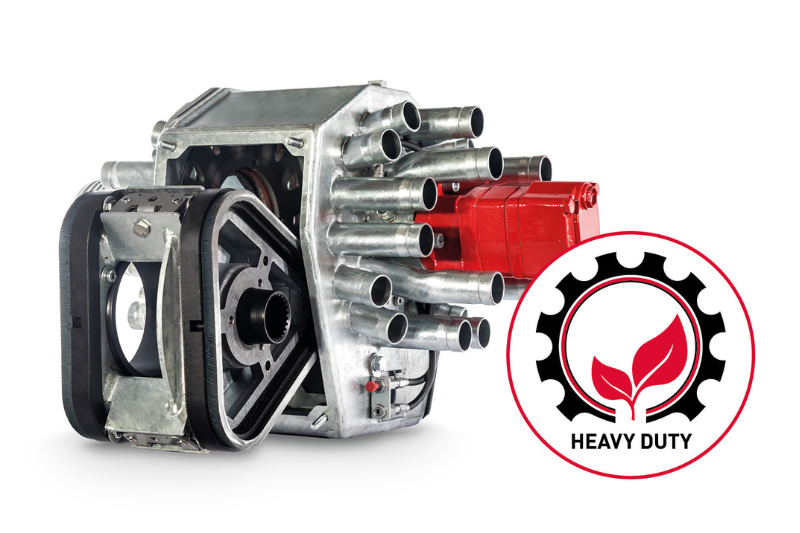

Versatility is at the core of the VX pump, handling a wide variety of media, from low viscosity to highly viscous, abrasive, or aggressive types. With quick access and easy maintenance, the pump chamber can be swiftly accessed by removing the cover, ensuring minimal downtime.

Built to withstand demanding conditions, this pump offers self-priming functionality, effortlessly drawing liquid from underground storage tanks. Its resilience against dry running ensures consistent performance, while break-proof shafts and HiFlo Lobes deliver smooth, pulsation-free pumping, maximising efficiency.

The non-foaming feature is particularly crucial when handling slurry or digestate, prone to foaming. This ensures the rotary lobe pump won't cause liquid foaming during operation, enabling complete tanker filling within weight limits. Therefore, the number of daily trips is reduced, leading to significant savings in road miles and fuel costs for operators.

The pump's design allows quick and easy access to all medium-affected parts without dismounting, simplifying servicing. The axial and radial wear plates and lined pump housing, made from highly wear-resistant special steel, extend maintenance intervals and make servicing a seamless process. The integrated foreign matter protection and a quality cartridge mechanical seal ensure top-notch reliability, safeguarding against potential issues.

“Choosing the VX 186-184Q rotary lobe pump over a traditional vacuum pump for the Crossland slurry tanker was a clear winner”

Richard O’Loughlin, Vogelsang Technical Consultant, explains the benefits of the VX 186-184Q, saying, "Its self-priming and non-foaming capabilities make it perfectly suited for their requirements. From the perspective of the tanker manufacturer, the absence of an internal vacuum in the tanker body allows for a lighter build, reducing engineering constraints. This lighter weight not only enhances operational efficiency but also increases the potential payload, which means fewer road miles and lower fuel costs for operators. It's a win-win all around."

Shaping the future of slurry transport

In the dynamic world of slurry transport, Vogelsang's VX Rotary Lobe Pump and Crossland Tankers' innovative Slurry Tanker join forces to redefine efficiency, reliability, and ease of use. This collaboration empowers farmers and the tanker sector to navigate their operations seamlessly, demonstrating the future of slurry transport. It's built on the foundation of Vogelsang and Crossland Tankers' commitment to meeting the needs of their customers and the tanker sector.

Further links

All about our VX Rotary Lobe Pumps