Perfect Timing

The railway depot in Hamburg-Langenfelde is setting itself up for optimal maintenance and repair of the latest generation of ICE trains

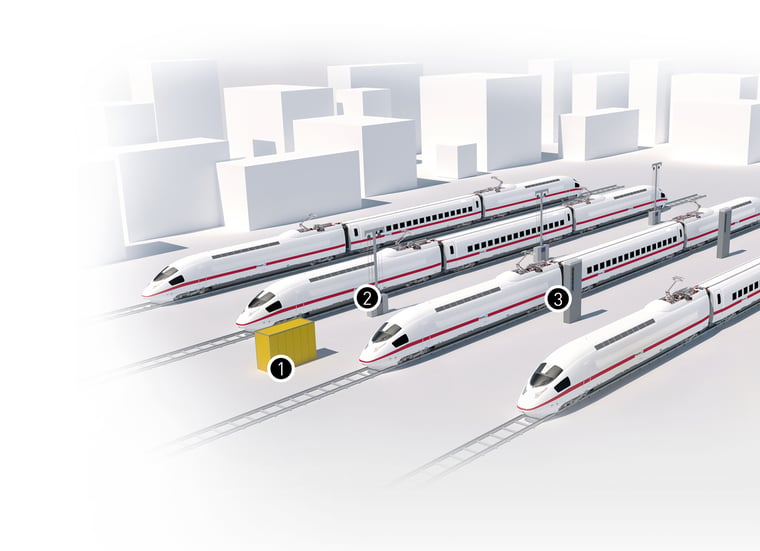

The railway depot in Hamburg is upgrading for Deutsche Bahn’s biggest fleet of trains to date. “Hamburg-Langenfelde will be one of the central home depots for the ICE 4 – the latest generation of ICEs. This will require construction work in many areas, such as increasing the size of the wagon shed,” explains Tino Behn, Project Manager at DB Netz AG. The certified engineer is in charge of the system infrastructure expansion at the Hamburg-Langenfelde rail depot.

DB Netz AG has been continuously expanding its systems for the cleaning of train interiors and the disposal and supply of water on trains since 2014. Due to the new flyover construction on the A7 freeway, which affects the northeastern section of the railway depot, maintenance capacities have been lost over the past few years. Similarly the construction measures at the railway depot due to the upgrading of the ICE 4 have restricted the use of existing maintenance facilities. Mr. Behn explains: “As a result, capacity indoors is no longer sufficient. The supply of water to trains had to be moved outdoors.”

Foundation consoles by Vogelsang speed up projects considerably

In extending its maintenance facilities, the company is safeguarding against possible bottlenecks at the depot. DB Netz AG therefore issued a call for tenders for new system components, which contained very specific requirements. The pump and supply/disposal units offered needed to be easy to operate to ensure maintenance and cleaning work can be carried out with the utmost efficiency and precision. To speed up installation, DB Netz AG also made ready-made construction elements a prerequisite in its call for tenders for the project. These ready-made construction parts were to weigh no more than 300 kilograms so they could be transported and loaded on the tracks easily by the special construction site vehicles. Vogelsang emerged triumphant from several tender processes thanks to its comprehensive range of solutions, which comprises a total of 75 systems: CleanUnits (cleaner cabinets) for the cleaning of train interiors, central VacUnits (vacuum pump stations) and TUnits for the filling of drinking water and the disposal of wastewater from trains. Out of the 75 systems, 35 were equipped with foundation consoles. Lightweight ready-made elements by Vogelsang and specially designed for the rail sector, foundation consoles contain all the required connections, pipes and cable conduits. As Mr. Behn explains: “This has made installation of systems much simpler and reduced the time required for the construction project significantly.” For underground construction work such as installation of lines for the electricity supply, drinking water pipes and other construction measures that form part of the preliminary performance could be carried out hand in hand with the subsequent installation of the foundation consoles and installation of the systems. According to Mr. Behn, the financial impact was equally positive: “Overall project costs were reduced due to the straightforwardness of the procedure.”

Due to construction space requirements at the site the equipment for drink water supply and

Due to construction space requirements at the site the equipment for drink water supply and

wastewater disposal for trains in Hamburg-Langenbehn had to be moved outdoors.

Vogelsang System components installed at the railway depot

VacUnit - The central vacuum station

The VacUnit vacuum pump station forms the central element of supply and disposal solutions by Vogelsang at the railway depot in Hamburg-Langenfelde. At its core are the required pump units in a redundant design and the corresponding central control system. A vacuum is generated and wastewater pumped at Hamburg- Langenfelde depot in three VacUnits, each of which uses two rotary lobe pumps of the VX series. Their redundant design ensures a high level of availability throughout the system. These positive displacement pumps are self-priming and designed to deliver viscous media. At the same time, they are resistant to foreign bodies and disruptive matter and easy to maintain. Directly connected to the sewage system, the VacUnits pump and dispose of wastewater efficiently in one single step.

Vogelsang System components installed at the railway depot

Vogelsang System components installed at the railway depot

TUnit - Supply and disposal system on the platform

The TUnits are installed on the platforms in the depot as integrated supply and disposal stations and connected to the central pump station (VacUnit). The network-station T-systems enable direct access to extraction and supply hoses and therefore rapid disposal of wastewater from the WC collection tank and supply of drinking water. The systems have a compact design and an automatic hose retraction device, as well as other user-friendly features such as an integrated cut-off mechanism.

CleanUnit - Professional cleaning station

The additionally installed media cabinets for cleaning, the Vogelsang CleanUnits, enable professional cleaning of train interiors by the personnel. Besides cleaning agents and equipment, the CleanUnits also provide cold and hot water as well as an environmentally friendly way of disposing of gray water. The compact CleanUnits, including all tools required for thorough cleaning of the train interiors, are available in just one location. This reduces the required time and legwork, enabling the trains to be cleaned as quickly as possible.

Project time reduced by a whole year

Unlike many projects involving large numbers of participants, delays to the schedule were avoided – quite the opposite in fact. When conceptualization and planning of the project began at the start of 2016, completion by the end of 2018 was envisaged by the responsible managers. The newly configured system for cleaning interiors as well as drinking water supply and wastewater disposal could be handed over to railway depot operators a whole year earlier than planned, in December 2017. The experts at Vogelsang also played a considerable part in this. Since then operation of the solutions has been successfully commenced, enabling efficient management of capacities by Deutsche Bahn. When required for peak operation, up to 30 staff can use the maintenance and servicing systems at the same time.

The combination of web-based checks and control modules on site ensures reliable operation of the systems.

The combination of web-based checks and control modules on site ensures reliable operation of the systems.

Central monitoring and remote maintenance

The online system developed by Vogelsang for the monitoring and control of system components, VEBSys, has also been set up in Hamburg-Langenfelde. The web-based monitoring app provides operating data for all the system components connected to the program regardless of their location, thus allowing engineers to reliably monitor which components are ready for operation. If a malfunction is detected, it can often be resolved by means of remote maintenance. On-site repairs – and the time and costs involved due to travel times and personnel requirements – are thus rarely required. The local control units (LCUs) are connected to the VEBSys online system. The LCUs can be used to control the valves in the supply and disposal equipment, for example. Automatic interlocking in the valves and other fixtures prevents the drinking water from being contaminated with wastewater due to operator error, for example. The combination of web-based inspections and control modules on-site enables comprehensive equipment quality control for operators in Hamburg and ensures that the systems run reliably and without interruption. This is essential to ensuring that the trains can be maintained in the time windows provided and keeping the logistics in the rail depot running smoothly.

Related Links

All about the segment Transportation

More about the Vogelsang TUnit

More about the Vogelsang VacUnit

More about the Vogelsang VebSys