Keeping Your Slurry Applicator and Macerator in Tip-Top Shape: Essential Tips for Field-Ready Performance

Get your slurry spreading technology ready to perform out in the field. As a farmer or contractor, having your slurry spreading equipment in excellent working condition is crucial for efficient and effective operations. Ensuring that your slurry applicator and its components, such as the macerator, are well-maintained especially after the season ends is not just good practice — it's essential for even distribution, uniform plant growth, and optimal nutrient management.

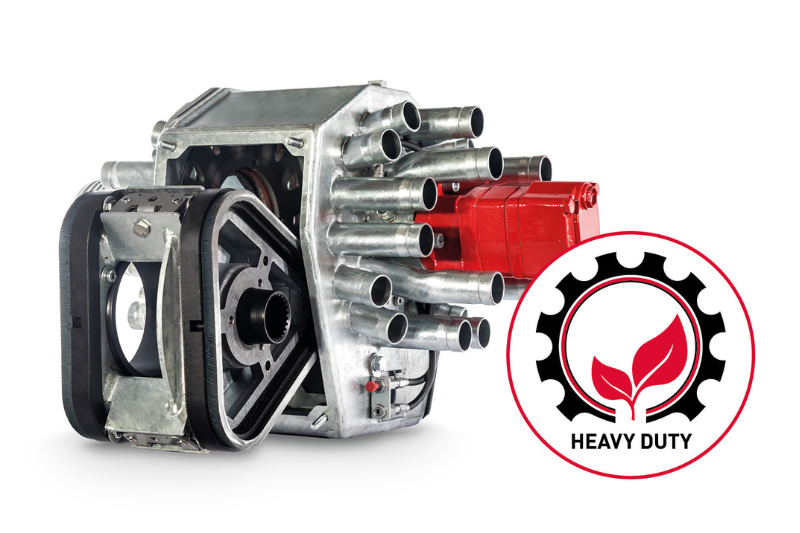

Here's how you can keep your slurry spreading technology fit for the field, featuring key maintenance steps using the Vogelsang SwingMax dribble bar system with heavy duty ExaCut ECQ macerator as an example.

Why Maintain Your Slurry Spreading System?

Regular maintenance of slurry applicators and their critical components, such as the macerator, is essential for achieving even and accurate slurry distribution. This level of precision not only ensures uniform nutrient application and consistent plant growth but also helps to prevent problems like blockages, uneven spreading, and costly breakdowns. Establishing a comprehensive Slurry Applicator Maintenance Plan, which covers cleaning and maintaining key components, is vital for keeping the equipment in optimal condition.

For example, the Vogelsang ExaCut ECQ macerator illustrates the benefits of proper upkeep. This robust macerator delivers high distribution accuracy and reduced wear, even when faced with the challenging field conditions in the Ireland. When combined with the SwingMax dribble bar system, which offers a working width of up to 21 metres, the ExaCut ECQ ensures consistent slurry flow across a wide area, highlighting the importance of regular maintenance for reliable and effective performance.

Essential Maintenance Tips for Your Dribble Bar System

Maintaining the dribble bar and trailing shoe system is key to effective slurry application. Here are three preventative maintenance tips:1. Inspect Hoses for Blockages and Damage

Over time, hoses can become clogged or damaged due to the nature of the material being spread. Regularly check each hose for debris, blockages, or signs of wear to ensure consistent flow across the system.

2. Clean OutletsThoroughly wash the exterior and the machine's pipework. This helps maintain the accuracy of the spread pattern and prevents uneven distribution.

3. Check Connection Points for LeaksInspect all connection points, seals, and clamps for leaks or looseness. Tighten or replace any worn parts to prevent slurry from escaping, which could reduce efficiency and increase clean up.

ExaCut ECQ Macerator Maintenance

The ExaCut ECQ macerator is engineered to handle demanding conditions, but regular maintenance ensures it operates at peak performance. Here are some critical steps:

1. Clear the Stone Trap

Stones or metal fragments in liquid manure are common, and the ExaCut ECQ’s stone trap separates these heavy materials. Open the trap regularly to remove foreign matter and ensure smooth operation.

2. Maintain the Air Duct

Spray water through the ventilation pipes while the macerator is running slowly. This prevents debris build up in the air duct, reducing the risk of blockages and enhancing overall air circulation.

3. Inspect for Wear and Tear

After cleaning, open the maintenance port and check the macerator for signs of wear. This routine inspection can help prevent unexpected breakdowns and extend the lifespan of your equipment.

4. Lubricate the Hydraulic Motor Adapter

After each cleaning, apply grease to the hydraulic motor adapter. This protects the seal, eliminates moisture, and reduces the chance of rust, ultimately enhancing the longevity of the macerator.

5. Care for the Cutting Surfaces

Cutting surfaces on the macerator benefit from a light spray or application of biodegradable oil. This reduces wear on blades, ensuring optimal cutting action and minimising clogging.

Completing these steps helps ensure even slurry spreading, maintaining your overall spreading system and main components like the macerator’s effectiveness. Once maintenance is finished, close the maintenance hatch and stone trap, secure the eccentric springs, and the equipment will be ready for the next spreading season.

For more information on Vogelsang macerator operating instructions, please visit the following links: ECQ Operating Instructions and ECL Operating Instructions. Additionally, for further guidance on maintaining Vogelsang macerators, explore our comprehensive video tutorials on the Vogelsang Service YouTube Channel.

Do you have any questions?

Whether you're new to slurry spreading or a seasoned professional, Vogelsang’s high-performance technologies and innovative components provide reliable solutions for efficient slurry management. From production to low-emission distribution, our equipment is designed to optimise nutrient efficiency and support sustainable farming practices. Reach out with any questions—we’re here to help you achieve precision, cost-effectiveness, and productivity with your slurry spreading operations.

To order your Vogelsang spare parts, contact your nearest Vogelsang dealer!

Learn more:

Vogelsang Agricultural Technology

YouTube Macerator Service Videos