Water 4.0

The digital revolution of waste water systems and its advantages

It’s known in Germany as “Industrie 4.0,” in France as “Industrie du future” and in the USA as the “Internet of Things (IoT).” Almost everyone has heard at least one of these buzzwords by now, and has a more or less accurate idea of what the fourth industrial revolution entails: Following on from mechanization, mass production and automation, we are now seeing an extensive computerization of production sequences and processes. The basis for this development is formed by structured, automated communication between people, machines, systems and logistics. The result will be a largely self-organized and flexible system that covers the entire value chain.

Greater efficiency through intelligent control technology and networking

The digital revolution isn’t stopping short of the waste water industry. Modern business models are successfully gaining a foothold in this sector, and not many people are complaining about the ongoing digitalization, despite the generally conservative attitudes of many involved in the field. Quite the opposite, in fact – after all, it makes their day-to-day work easier. Due to their large numbers of decentralized pump stations and other structures, waste water companies in particular can benefit from networking all their components together using modern IT and based on model applications. Of course, special solutions tailored to the specific requirements of the waste water sector are required in order to cover the entirety of the complex waste water infrastructure. After all, sewer systems and sewage treatment plants are part of what is known as the “critical infrastructure” – systems whose operational safety is of particular importance to a functioning society. At the same time, everyone involved is aware of their responsibility to ensure that costs are kept as low as possible in the interests of the public. Procedures, decision-making and early-warning processes need to be structured in such a way that everyone involved benefits from the flow of

information and can respond accordingly. One example of this would be using the local weather forecast to prepare the sewer system and local sewage treatment plants for heavy rainfall. Individually adapted, intelligent control technology, networking and communication will not only make plant operation safer and more flexible – it will also make them more efficient, which will in turn have a positive effect on costs and working hours.

Smart systems and modern control modules for processes that run smoothly

In the sewer system, this is mainly dependent on smart pump systems, which are often fitted with a waste

water grinder. However, this doesn’t necessarily mean replacing the entire technology – it is often enough to simply update the technology that is already installed and add a new controller. Modern controllers, such

as the latest generation of the Vogelsang Performance Control Unit (PCU), are designed to handle the specialist requirements of wastewater in combination with the Internet of Things without neglecting any of

the important functions provided by their predecessors.

They still monitor actual and rated values, detect malfunctions and fix them automatically. The PCU also

handles the independent control of systems comprising multiple pumps and grinders in an optimum range. Redundant systems are controlled dependent on operating hours.

Thanks to ProfiNet, the open industry standard for automation, the machine and controller can also

communicate quickly with one another and the higher-order system. All the operating data, such as the power consumption, overload and insufficient load, capacity or flow rate, and negative or over pressure on

the pressure and suction sides can be collected and called up for analysis. On top of this, the PCU can be

equipped with Wi-Fi access and then operated using a tablet or smartphone. An OPC UA interface enables

cross-platform data exchange via a separate network, an intranet or the Internet. This allows the user to

update their controller and enable it to be accessed for remote maintenance.

.jpg?width=760&name=wastewater-mood-image--vgs2137%20(1).jpg) For example, the local weather forecast can be used to prepare the sewer system and the local sewage treatment plant for heavy rainfall.

For example, the local weather forecast can be used to prepare the sewer system and the local sewage treatment plant for heavy rainfall.

Simple handling and greater transparency for targeted management

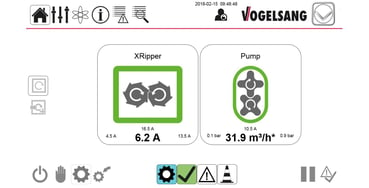

In order to make it as simple as possible for the user to access the data they require, the Vogelsang

PCU’s HTML-based user interface uses easy-to-follow visual elements and an intuitive navigation system. Operating statuses, operating data and settings are displayed clearly, made easily accessible and can be adjusted without any complications. Any messages and alarms are documented precisely to the second, after which they can be selected immediately.

As well as allowing direct monitoring and control, the continually collected operating data are used together with noteworthy key figures and operating statuses as the bases for a “virtual twin” of the sewage system. The introduction of this level allows users to simulate a wide range of scenarios in order to find solutions for malfunctions and develop optimized usage models without affecting – or even blocking up – the actual infrastructure.

The Vogelsang PCU’s HTML-based user interface uses easy-to-follow visual elements and an intuitive navigation system.