Millions in damage caused by wet wipes

Episode 1: How wet wipes turn into sewer monsters

Operators of sewage systems like waste water associations or municipalities have been facing a new challenge in recent times: More and more hygiene products and disposable cosmetic products are not thrown in the trash, they end up in the toilet and then in the sewage system.

Even though they have no business being there, operators find large quantities of disposable wipes, cotton buds, tampons and panty liners, plasters, clothing and other textiles in sewers and sewage treatment plants. However, the biggest problem is the masses of wet wipes and baby wipes. In addition, water consumption in private households has decreased significantly. Though this would appear to indicate a higher awareness of how precious water is, it only exacerbates the problem with wet wipes, etc., as they are even less likely to dissolve and flow off. As a result, the waste water associations and municipalities must invest significant resources in ensuring that the sewage system functions smoothly, while also keeping the waste water charges as low as possible.

Incorrect disposal causes problems

In particular, sales of wet wipes have increased strongly in many countries: in Germany in recent years by around 200%. Whereas in the past they were used almost exclusively for baby care and were thrown out in household garbage together with diapers, wet wipes are now part of day-to-day hygiene and are thrown into the toilet more and more frequently after use. More and more fibers are ending up in the sewer system with less and less waste water. In addition to this, the wipes only decompose very slowly or not at all – a combination that inevitably clogs the pumps in the sewage system.

That makes the maintenance workload for operators all the greater, also increasing the waste water charges for consumers.

Even it is illegal in some countries to throw wet wipes or similar items into the toilet, only few consumers are aware of this. However, warnings to throw them out in household garbage are either so inconspicuous that consumers overlook them, or are absent completely.

The seven stages of flushability

Instead, details on flushability can be found on many wet wipe packages. These are based on a voluntary test initiated by the European Association of Nonwoven Manufacturers, EDANA, with respect to the flushability of wet wipes in toilets.

However, in the opinion of experts, these seven stages of flushability do not take the full scope of the wet wipe problem and its effect on sewers into account, as the test finishes just after the toilet’s waste water pipe. It does not pay sufficient attention to whether and how fast the highly fibrous wet and cosmetic wipes disintegrate in the sewer system at all, say the experts.

What is known is that the length of time wet wipes need to decompose depends very much on the type of nonwoven. One thing is certain however: more and more undecomposed wet wipes are clogging pumps and reaching sewage treatment plants entirely intact. The length of time they remain in the sewer system

is much too short for more extensive decomposition to occur.

And the phenomenon does not end with wet wipes. Other hygiene products like clothing and textiles are increasingly also being disposed of via sewage pipes.

The low prices of everyday items shorten their service life; their value is not appreciated enough. Especially underwear or cleaning cloths and rags are being flushed away instead of being disposed in the rubbish bins – an additional fiber load in the sewage system, which quickly overloads conventional waste water technology.

Other modern hygiene products like clothing and textiles are increasingly also ending up in sewage pipes.

Other modern hygiene products like clothing and textiles are increasingly also ending up in sewage pipes.

Fibers as a cause for clogging of pumps, screens and waste water pipes

Very few hygiene products and textiles are easy to separate.

Wet wipes in particular are a problem for the technology in sewage systems, as they tend to get entangled. However, the resulting contaminant tangles never untangle themselves on their own. Instead, technical components regularly fail because pumps, fittings and waste water pipes are clogged. Even pumps developed by the industry with freewheel, i.e., with a large free passage, can only handle these entangled fibers and the clumps to a limited degree. At the same time, operators have to accept a significant drop in efficiency in pumps equipped in this way.

Entangled material due to undecomposed fibers - Shredded tangles by upstream twin-shaft grinder like the XRipper

Entangled material due to undecomposed fibers - Shredded tangles by upstream twin-shaft grinder like the XRipper

High costs due to clogging in more and more countries

The great media attention in some countries for the wet wipe problem may seem like scaremongering, but weekly to daily removal of clogging is more and more part of the standard routine in several countries. Henning Werker, head engineer at the Cologne Sewage Treatment Department, estimates the annual costs of cleaning the pumps in the city’s five sewage treatment plants at roughly 500,000 euros. Wet wipes have been identified as the main cause of this. The Berlin Municipal Water Authority even estimates the costs caused by problems with wet wipes to be as high as 800,000 euros per year. The German Government estimates nationwide, the total is likely to be a high eight-figure sum.

Solution in sight: Safe protection with twin-shaft waste water grinder

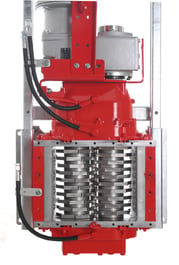

Entangled wet wipes can generally only be prevented if these are shredded before they reach the first pump. One economic variant for reliable protection from clogging of pumps and waste water pipelines is twinshaft grinders like Vogelsang’s XRipper.

Entangled wet wipes can generally only be prevented if these are shredded before they reach the first pump. One economic variant for reliable protection from clogging of pumps and waste water pipelines is twinshaft grinders like Vogelsang’s XRipper.

The XRipper is based on a contactless principle of operation, which is why it's power requirements are minimal while idle. Thanks to the low speeds, large torques are made available for shredding, enabling these devices to prevent the clogging of pumps or waste water pipelines, even with a low drive power. For many operators, investing in this kind of technology pays for itself within a very short time as a result.

Power consumption and thus the operating costs of the pumps decrease, avoiding cost-intensive maintenance and service deployment. In particular, emergency deployments at night and on public holidays caused by clogged pumps incur high costs for waste water companies.

XRipper twin-shaft grinder installed upstream of the outlet of an open waste water collection shaft

XRipper twin-shaft grinder installed upstream of the outlet of an open waste water collection shaft

Further links

More about the wastewater segment

Discover the virutal showroom for wastewater technology