Twin-shaft grinder vs. macerator

.png)

Safe and reliable wastewater disposal and purification is becoming increasingly important in order to protect waters and the environment and maintain a high quality of life. At the same time, sewage systems are increasingly struggling with fat bergs and wet wipes, which drive up operating costs. This makes it all the more important to integrate efficient and reliable wastewater treatment technologies.

We will tell you how you can reliably reduce solids with the right equipment and thus protect your pumps and systems from harmful foreign matter.

Debris and foreign matter challenge sewer systems

Hygiene products such as wet wipes and other harmful matter are increasingly finding their way into our wastewater systems. There they are the cause of rags and blockages in the sewer system and wastewater treatment plants. However, the screens in these systems, which remove the majority of impurities, cannot catch everything. As a rule, fibers and foreign matter continue to enter the systems, including wet wipes, textiles, hair, plastic parts, cotton swabs, pieces of wood and much more. These increase maintenance costs and generate additional costs for troubleshooting and spare parts. Problems with pumps, valves and other equipment are therefore becoming more frequent.

To counteract this problem, you can protect your pumps and systems with special technology. This treats harmful matter so that they can continue to flow with the wastewater. Depending on the application, there are two different systems to choose from: Twin-shaft grinder or macerators with an integrated heavy material separator. But when does which technology make the most sense?

The RotaCut macerator

The RotaCut specializes in effectively cutting suspended and fibrous materials that flow through it. Heavy foreign bodies such as stones or metal parts are not cutted but separated in the integrated heavy material separator. The RotaCut macerator from Vogelsang delivers the best results when it is installed after the screen. As it reliably chop down solids and fibrous materials, it is particularly advantageous to install it upstream at the following points:

1. The feeding of a digestion tower

The treatment of solids and fibrous materials plays an important role in the feeding of a digestion tower. If you use the RotaCut macerator upstream of the digestion tower, floating layers in the digestion tower are avoided in the long term thanks to the treatment of foreign matter. You can also counteract the tendency to form rags. A macerator therefore offers you reliable protection against clogging of the recirculation pumps. As a result, maintenance or malfunctions occur much less frequently - saving you time and money.

2. The treatment of sludge before dewatering

A macerator is ideal for breaking up smaller rags and reliably homogenizes the sludge. Dewatering runs more evenly, is better and less sludge needs to be disposed of at the end. This sustainably reduces costs and ensures more efficient operation of your plant.

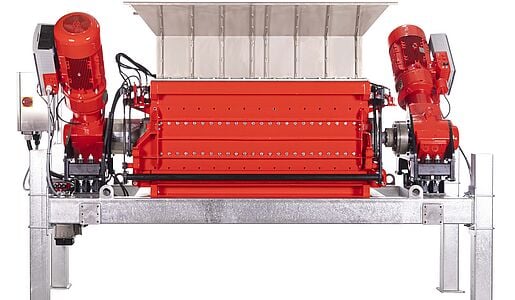

The XRipper - a twin-shaft grinder

A twin-shaft grinder has two counter-rotating rotors with many teeth. These are the so-called ripper rotors. During operation, these pull the solids from the housing wall to the center, where the solids are shredded to an unproblematic size. Meanwhile, the wastewater can pass through the grinder largely unhindered.

This technology makes the XRipper a very economical solution for shredding solids such as hygiene articles, rags or waste in the sewage system or in the inlet of the sewage treatment plant. The XRipper twin-shaft grinder also performs reliably in the digestion tower circulation system. Even larger rags are reliably shredded, even though they can sometimes be 2 meters long. In this way, the XRipper prevents clogging of pumps, valves and fittings and ensures trouble-free digester operation.

Your individual grinding solution

Every system is different, but one thing is certain: Vogelsang's twin-shaft grinder are suitable for most applications in which you want to reduce solids in wastewater to an unproblematic size. However, the RotaCut macerator delivers better results for wastewater purification process steps such as sludge thickening or digestion tower feeding.

Do you need further information or help choosing the ideal macerator? Then get in touch with our wastewater experts - we look forward to hearing from you and will be happy to assist you with our combined expertise.

Further Links