A sticky affair

-1.png)

Rotary lobe pump tackles highly viscous media

In industry, pumping molasses is one of the gold-standard disciplines for pumps. The highly viscous sugar syrup is created as a by-product of sugar production and places high demands on the pump technology due to its extreme viscosity.

Pumping highly viscous media trouble-free

The varying consistency of the sugar syrup poses another challenge: “The viscosity of the mass depends on various factors, such as the country of origin, temperature and whether it is molasses from sugar cane or sugar beet,” explains Uwe Vittinghoff, Operations Manager at Hansa Melasse Handelsgesellschaft mbH in Bremen.

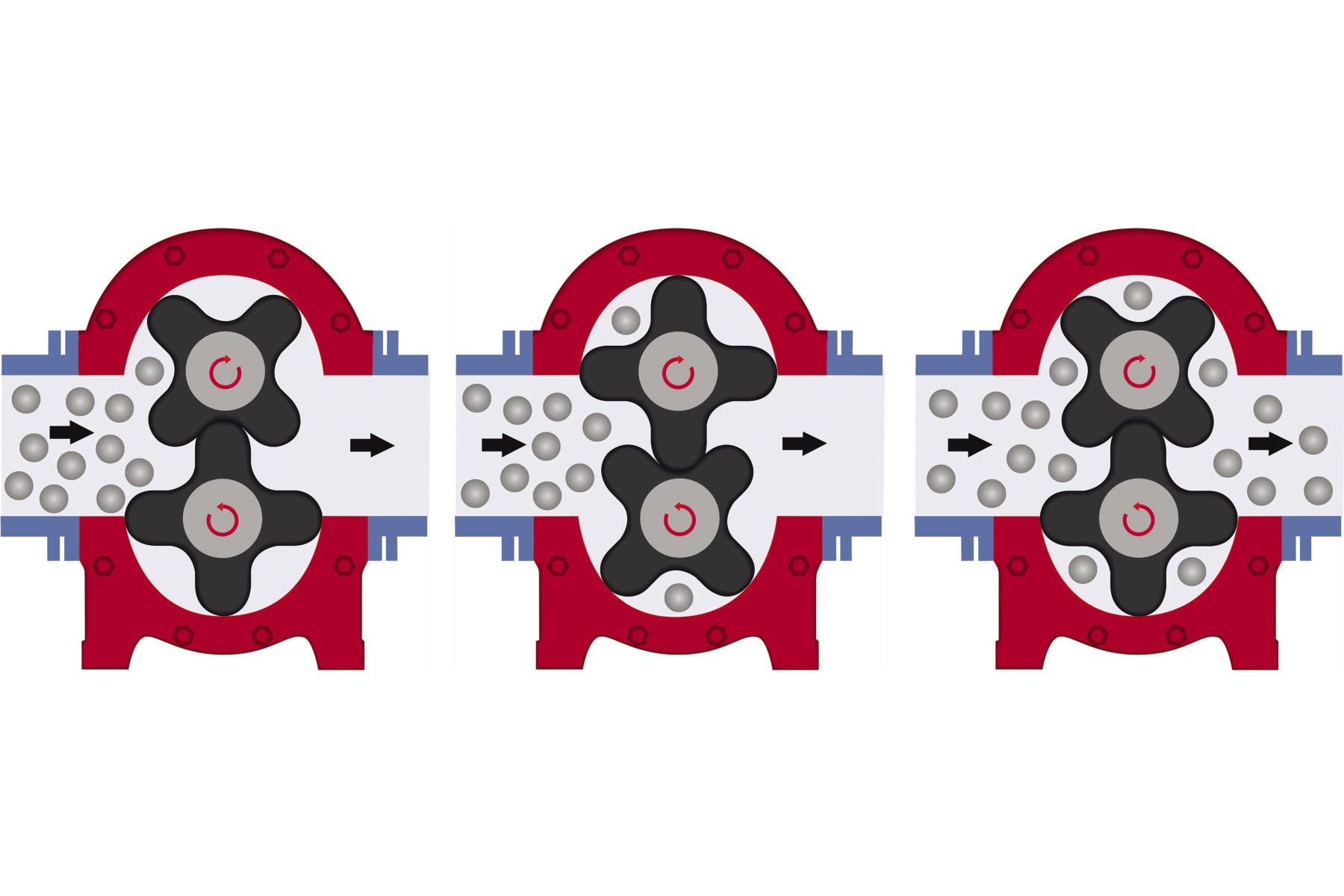

Rotary lobe pumps from Vogelsang represent the ideal solution here because they can pump even media with changing viscosity with consistently reliable power and no performance impairment – even over long distances on an upward gradient. They can pump highly viscous or aggressive media of all kinds and can even pump fluids with coarse solid matter without being clogged.

Use case: Hansa Melasse Handelsgesellschaft mbH in the Bremen tank farm

Tank farm applications make significant demands on the pumps due to the many transport processes. For

example, the sugar syrup has to be filled into storage tanks from ships and into trucks or intermediate bulk

containers (IBCs) from the tanks.

The company, which is specialized in the procurement and sale of molasses and related products, also faces this challenge. The company simultaneously relies on several Vogelsang VX series rotary lobe pumps to ensure reliable pumping of the sugar syrup. These pumps are used at the tank farm in Bremen to transport the molasses from a jetty on the site into one of three storage tanks on the shore. The company uses other VX series pumps, some of which are mobile, for subsequent filling of tank trucks and IBCs.

For almost 20 years, Hansa Melasse has trusted rotary lobe pumps from Vogelsang for trouble-free pumping of its demanding product – so even the stickiest syrup can be pumped reliably from station to station.

The viscosity of molasse depends on variable factors

Temperature

In summer, the molasses is thinner due to the higher temperature and therefore easier to pump than in winter.

Geography

The viscosity differs depending on the country of origin or even the producer. This is due, among other things, to the different composition of the molasses during the production process.

Origin

The flowability of molasses also varies depending on the starting product, whether sugar cane or sugar beet.

Advantages of Vogelsang rotary lobe pumps for pumping molasses

- Self-priming and resistant to dry running and foreign matter

This reduces wear and tear, increases system availability and enables a trouble-free pumping process even when the tank is being emptied. - Pulsation-free running

The molasses is pumped gently and without foaming. Sugar crystals pass through the process

undamaged.

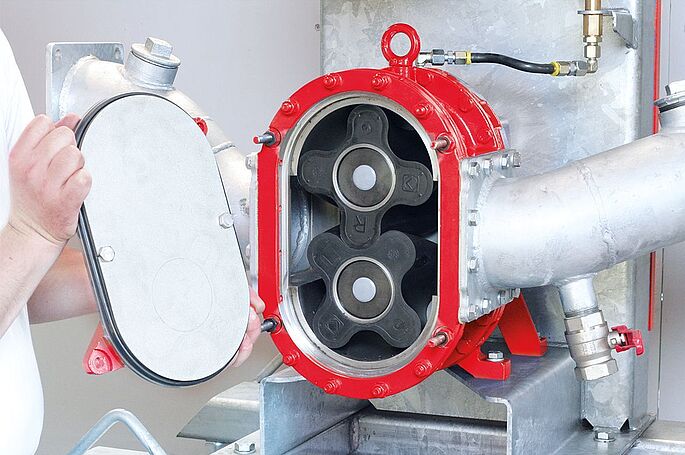

- Maintenance-friendly and compact

In-house employees can carry out all maintenance work without dismantling the pumps, thus minimizing downtime. Due to their compact design, Vogelsang pumps can be integrated into any system.