Abrasive media? Vogelsang industrial pumps provide effective help

We live in a connected world and benefit every day from the industrial infrastructure that gives us easy access to food and raw materials. Transport vehicles are an essential part of this infrastructure. These transport media, some of which are highly viscous, but also aggressive. What role do rotary lobe pumps play in this context and how can they help to improve safety and efficiency?

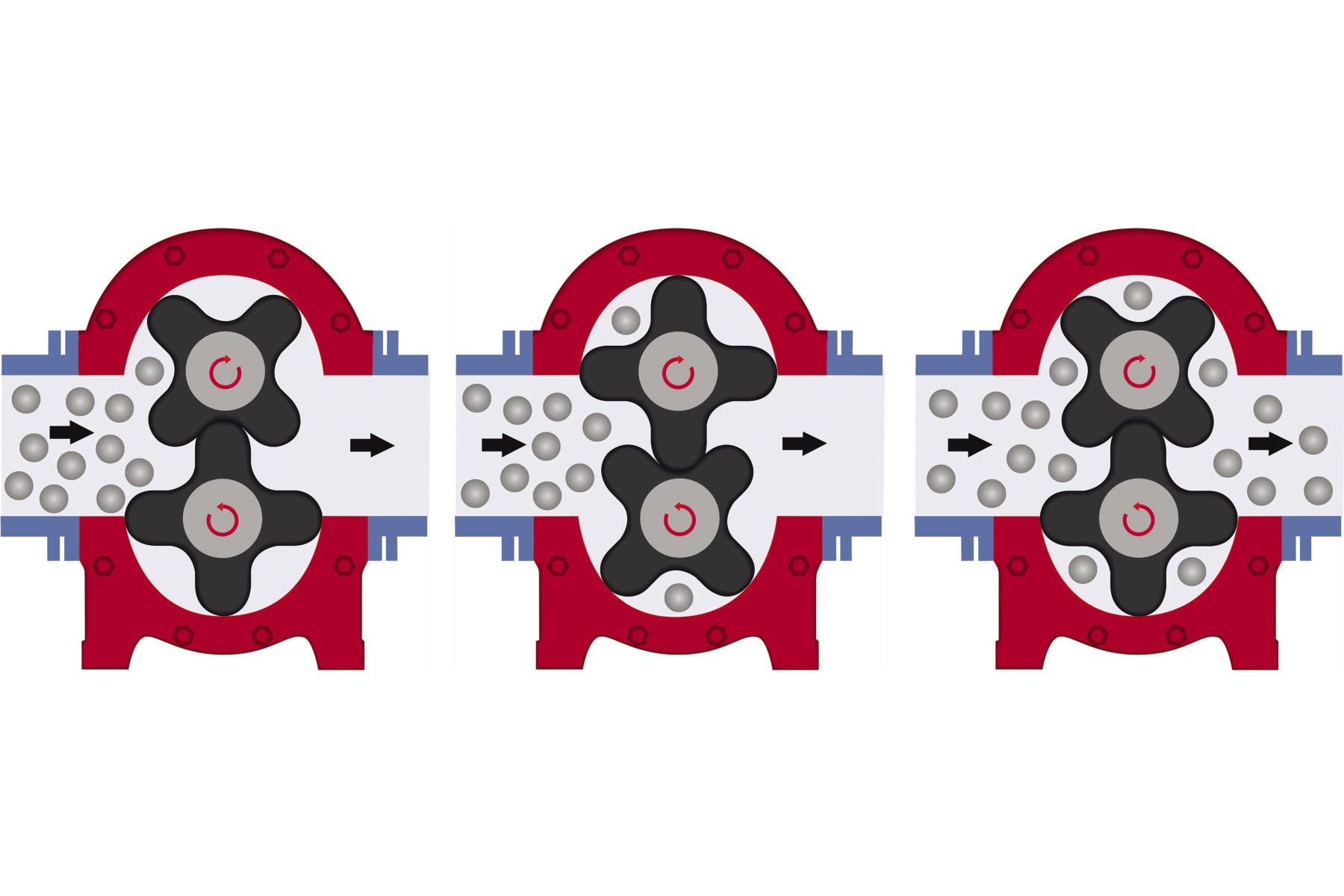

How do Vogelsang rotary lobe pumps work

Rotary lobe pumps are part of a group of pumps known as positive displacement pumps. The pumping principle is created by two counter-rotating pumping elements mounted on two synchronous shafts. This creates a vacuum which sucks the medium in question into the pump (self-priming). The medium is then trapped in the resulting cavities and pumped directly.

Vogelsang's rotary lobe pumps have a variable delivery direction, which is why the installation of one pump is sufficient. This saves both labor and time The pumps have a compact design and are capable of handling even highly viscous or aggressive materials without risking blockage. This is due to the special design, which is extremely robust and low in pulsation.

The VX series

The VX-Serie rotary lobe pump impresses with its wide range of applications. It is also self-priming and resistant to dry running and foreign objects. Maintenance is also easy, thanks to access to the pump chamber through quick removal of the cover. The resulting intensive economic operation results in financial benefits for users.

The IQ-Serie

The one-piece housing of the IQ-Serie consists of fewer individual parts and, like the VX series, offers fast and optimal access to the lobes. It is available in several sizes and can be adapted to customer requirements in terms of pressure and flow rate.

How can rotary lobe pumps help the logistics industry?

Transporting aggressive and highly viscous media is a challenge for logistics companies. In order to be able to prioritize occupational safety and economic efficiency, it is particularly important that accurate filling and emptying of transport vehicles takes place. Vogelsang rotary lobe pumps can be operated in both directions. This means that discharging and filling operations can be carried out with the same pump, eliminating the need to install a second pump. This saves a lot of space and weight, so the tank truck has a lower weight which again allows for a larger load. Due to the ease of maintenance and easy access to the inside of the pump, the pump can be mounted on the vehicle and in the pipeline for any maintenance work.

Safe transport of chemical products

Chemically aggressive media presents special challenges for transport companies. During use, the pumps come into direct contact with the abrasive materials and must accordingly be resistant to them.

This is achieved by lining the pump chamber with radial and axial protection plates, which reduce wear and can be replaced very easily.

The media that can be successfully transported with the help of Vogelsang rotary lobe pumps are, for example:

- Fish and vegetable oils

- Used vegetable oil

- Antifreeze

- Waste products from the oil and gas industry

- Most, Beer and Pomace

- Molasses

- Glycerine

- Bentonite

- Hydrocarbons

- and much more

Reduction of maintenance and material costs

If pumps in the context of tank trucks regularly come into contact with particularly abrasive substances, this can be a costly problem. This is because media such as oil or hydrocarbons cause particularly rapid wear of the machines that come into contact with them. This problem affects various industries, but especially recycling companies. This is because recycling companies often transport media such as contaminated fuels or oil separator contents, which severely attack the materials they come into contact with. Accordingly, high maintenance and material costs are incurred by using the pump.

The Vogelsang rotary lobe pumps provide a compact and easy-to-maintain solution that can be installed even in the smallest spaces. Thanks to special materials, an above-average durability of the pumps can be guaranteed. Contact parts are made of stainless steel or Super-Duplex to withstand the increased corrosion attack. Should corrosion nevertheless occur in the long term, attacked pistons and also the mechanical seal as individual parts can be flexibly removed and replaced thanks to the QuickService design.

Facilitating everyday work

With the right technical equipment, you can master even the most demanding challenges of everyday work. Vogelsang's particularly corrosion-resistant industrial pumps and rotary lobe pumps are available to you with full flexibility and effectiveness!